- NON-CORROSIVE: PP PIPES CAN WITHSTAND PH VALUES OVER A WIDE RANGE OF TEMPERATURES. Corrosion of high concentrations of acids and alkalis in the range of 1~14.

- Wear-resistant, non-scaling: The inner wall of PP pipes and fittings is uniform and smooth, with low flow resistance and no scaling.

- Reduced vibration and noise: PP pipes have excellent sound insulation properties, which can significantly reduce vibration and noise caused by liquid flow.

- Anti-freeze cracking: PP material has excellent elasticity, so that the cross-section of the pipe and pipe fittings can expand with the liquid of frost heaving without swelling.

- Anti-condensation, less heat loss: PP material is a poor conductor of heat, which can reduce condensation and reduce heat loss.

- Simple installation: PP pipe is light in weight, easy to install and operate, and has weldability.

- Long service life: The PP pipe system has a service life of up to 50 years under the specified use conditions.

PP pipes Overview of crystallization properties

- Because of the high crystallinity, the surface stiffness and scratch resistance characteristics of the PP pipe are good, so there is no problem of stress cracking.

- The low MFR PP pipe data has better impact resistance characteristics but lower elongation strength. For the same MFR, the strength of the copolymer type is higher than that of the homopolymer type. Because of crystallization, the shortening rate of PP is quite high, usually 1.8~2.5%.

- The strength of PP pipe increases with the addition of ethylene content. The Vicat softening temperature of PP is 150°C. In the market, PP is generally modified by means of glass fiber, metal additives or thermoplastic rubber.

- PP pipe is a semi-crystalline material. It is stronger than PE and has a higher melting point. Because the homopolymer type PP pipe is very brittle when the temperature is higher than 0 °C, many trade PP materials are unconventional copolymers with 1~4% ethylene or clamp copolymers with higher ethylene content. The copolymer type of PP material has a lower thermal distortion temperature (100°C), low clarity, low gloss, low rigidity, but has stronger impact strength. The MFR of PP activity rate is limited to 1~40. Moreover, the bias of the shortening rate is much better than that of data such as PE-HD. The addition of 30% glass additives can reduce the shortening rate to 0.7%. Both homopolymer and copolymer PP materials have excellent resistance to moisture absorption, acid and alkali erosion, and ablation. However, it has no resistance to aromatic hydrocarbon (e.g. benzene) solvents, chlorinated hydrocarbon (carbon tetrachloride) solvents, etc. PP pipes are also not oxidation resistant at high temperatures like PE.

The production of PP elbow and precautions

1. Bending of the tube:

(1) The tubes of DW≤219 are cold-formed as much as possible;

(2) DW>219 uses prefabricated elbows. If there is no top elbow at any angle, shrimp knot bend can be used.

PP pipe installation details and precautions

- When installing PP pipes, the influence of ambient temperature on the installation quality should be considered, and when the general temperature is higher than 40 °C or lower than 0 °C, it is not suitable for construction and installation.

- Due to the large expansion coefficient of PP pipelines, thermal compensation should be considered during installation, and natural compensation is generally the mainstay, such as the use of square telescopic devices.

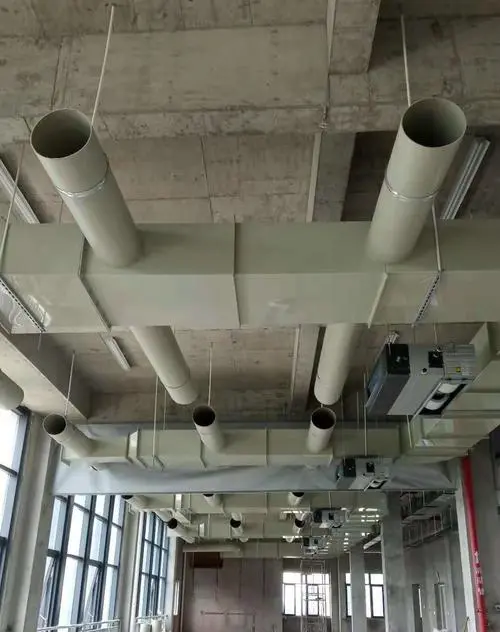

- When the PP pipe is laid overhead, the pipe should be supported by pipe support, and the pipe support can be made of angle steel, steel pipe and other materials, so that the reinforced polypropylene can be freely expanded and contracted on the pipe support.

- When the PP pipe needs to be concealed. It is recommended to use pipe trench laying, the pipe is generally welded connection type, if it is necessary to bury the ground for special reasons, it should be buried directly in the form of casing, so as to avoid mixing hard debris in the backfill and reporting the broken pipe.

- When the PP pipe is connected by flange, it should be strictly centered, and the maximum allowable deviation of the axial direction is not more than 2mm, and the method of forced tightening of the bolt shall not be used to adjust, and the tightening bolt shall be carried out in two times, and the first time it shall be screwed evenly and symmetrically according to the diagonal, and then the bolt shall be tightened.