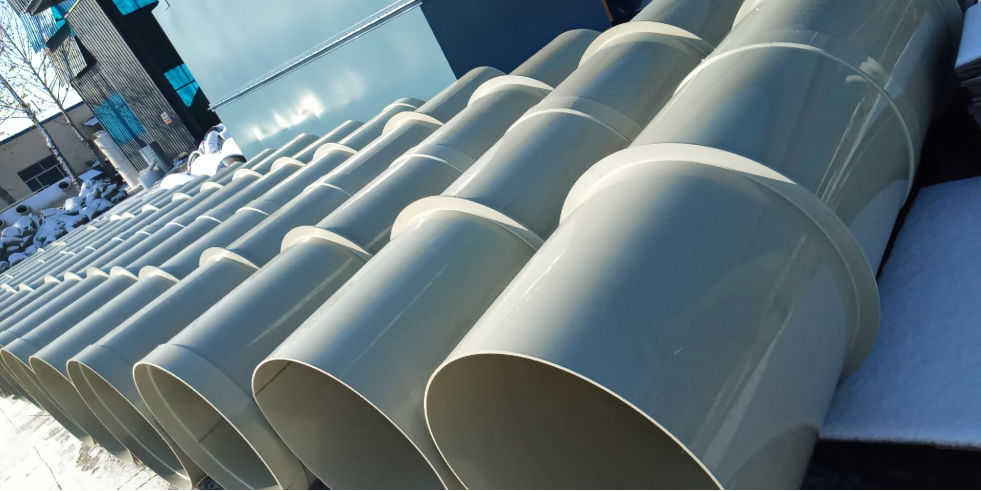

PP flame retardant pipe is a safe fireproof pipe, it has the advantages of wear resistance, corrosion resistance and frost resistance, and is currently widely used in industry, civil engineering, medicine and food and other fields.

The testing laboratory for rubber and plastic materials can provide all kinds of PP flame retardant pipe testing services, including flame retardant performance testing, chemical composition analysis, chemical stability testing, tensile strength, etc.

The following is how to distinguish the good and bad PP flame retardant pipe

(1) The appearance quality of the elbow is: there should be no cracks, scars, burns, wrinkles, delamination and other shortcomings. If there are such shortcomings, they should be removed as much as possible, and the wall thickness of the removed part should be thinned within the allowable range of the wall thickness reduction rate, otherwise it should be scrapped.

(2) Pipe wall crease height: PP pipe is allowed to wrinkle evenly after bending, but the wrinkle height should not exceed 3% of the outer diameter of the pipe, and should not exceed 5% as much as possible.

(3) Pipe shrinkage: Calibration of PP pipe: Before formal installation, it is allowed to calibrate the pipe by thermal processing. After the hot work calibration, the pipe should be galvanized as required (some areas can only be galvanized) or other maintenance.

PP flame retardant pipe testing items

Combustion performance test, smoke density test, flame retardant performance test, chemical composition analysis, chemical stability test, tensile strength, tensile modulus, flexural strength, flexural modulus, hardness, aging test, electrical performance test, weather resistance test, strength test, mechanical property test, ROHS test, REACH test, etc

PP flame retardant grade classification

The grade standard is the UL-94 flame retardant plastic standard, and the flame retardant grade is divided into HB, V2, V1, V0, 5VB, and 5VA, and the flame retardant grade is increasing sequentially. The fireproof PP flame retardant grade of plastic is also in accordance with this standard.

- HB: The lowest flame retardant rating in the UL94 standard. Requires a burning rate of less than 40 mm per minute for samples between 3 and 13 mm thick; Samples less than 3 mm thick with a burning rate of less than 70 mm per minute; Or extinguish in front of a 100mm sign.

- V-2: After two 10-second burn tests on the sample, the flame is extinguished within 60 seconds. Incendiary objects can fall.

- V-1: The flame is extinguished within 60 seconds after two 10-second burn tests on the sample. No incendiary material can fall after the combustion is completed.

- V-0: The flame is extinguished within 30 seconds after two 10-second burn tests on the sample. No combustibles can fall after extinguishing.

- 5VB: After five 5-second burn tests on the sample, the afterflame/afterburn is extinguished within 60 seconds. Dripping particles do not ignite cotton.For square-shaped samples, burn-through is allowed.

- 5VA: After five 5-second burn tests on the sample, the afterflame/afterburn is extinguished within 30 seconds. Dripping particles do not ignite cotton. For square samples, it is not allowed to burn through.

- Compared with other general-purpose thermoplastics, modified PP has the smallest density of 0.90-0.91 grams per cubic centimeter, excellent mechanical properties such as tensile strength, compressive strength, surface hardness and elastic modulus, and outstanding stress crack resistance and wear resistance. PP has good heat resistance, it can be heated to 150 degrees without deformation in an environment without external force, it can be boiled in boiling water, and it can be used stably for a long time above 100 degrees.

- PP almost does not absorb water, has excellent chemical stability, in addition to oleum and strong oxidant, the rest of the medium is very stable, its high-frequency electrical performance is excellent, and is not affected by temperature, easy to mold processing, can be used injection molding, extrusion and hollow molding and other methods to form a variety of products.