Vinyl chloride processing material

- Profiles and processed profiles are the largest areas of PVC consumption in China, accounting for about 25% of the total consumption of PVC, mainly used to make doors and windows and energy-saving materials, and their application is still growing significantly in the country. In developed countries, the market share of plastic doors and windows is also the highest, such as 50% in Germany, 56% in France, and 45% in United States.

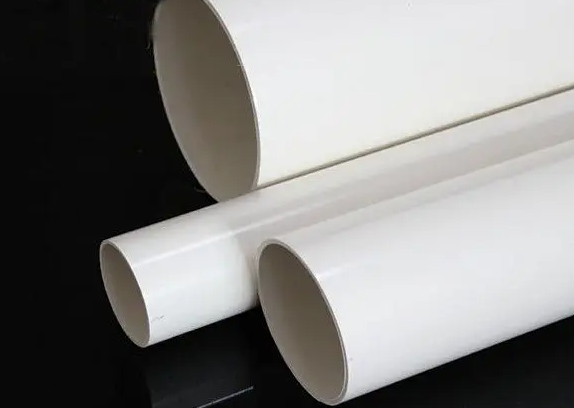

PVC pipes

- Among the many PVC products, PVC pipes are its second largest consumption area, accounting for about 20% of its consumption. In China, PVC pipes were developed earlier than PE pipes and PP pipes, with many varieties, excellent performance and wide range of use, and occupy an important position in the market.

PVC film

- The consumption of PVC in the field of PVC film ranks third, accounting for about 10%. After PVC is mixed with additives and plasticized, a three- or four-roll calender is used to form a transparent or colored film of a specified thickness, and the film is processed in this way to become a calendered film. It can also be cut and heat-sealed to process packaging bags, raincoats, tablecloths, curtains, inflatable toys, etc. Wide, transparent films can be used in greenhouses, plastic greenhouses and mulch films. Biaxially oriented film can be used for shrink wrapping due to heat shrinkage.

PVC hard materials and sheets

- Stabilizers, lubricants and fillers are added to PVC, and after mixing, the extruder can be used to extrude rigid pipes, special-shaped pipes and corrugated pipes of various calibers for use as sewer pipes, drinking water pipes, wire sleeves or stair handrails. The calendered sheets are superimposed and hot-pressed to make rigid sheets of various thicknesses. The sheets can be cut into the desired shape and then welded with hot air using PVC electrodes into a variety of chemically resistant tanks, air ducts and containers.

PVC soft products

- The extruder can be extruded into hoses, cables, wires, etc.; Using injection molding machines with various molds, it can be made into plastic sandals, shoe soles, slippers, toys, auto parts, etc.

PVC packaging material

- Polyvinyl chloride products are mainly used for packaging, mainly in various containers, films and rigid sheets. PVC containers are mainly used in the production of mineral water, beverages, cosmetic bottles, and also for packaging of refined oils. PVC film can be used to co-extrude with other polymers for low-cost laminates, as well as transparent products with good barrier properties. PVC film can also be used in stretch or heat shrink wrap for mattresses, fabrics, toys, and industrial goods.

PVC wainscoting and flooring

- PVC wainscoting is mainly used to replace aluminum wainscoting. In addition to a part of PVC resin, the rest of the components in PVC floor tiles are recycled materials, adhesives, fillers and other components, which are mainly used in the hard ground of airport terminals and other places.

Polyvinyl chloride consumer goods

- Luggage bags are a traditional product made from PVC, which is used to make a variety of imitation leather, used in luggage, sports products such as basketball, football and rugby. It can also be used to make belts for uniforms and special protective equipment. PVC fabrics for clothing are generally adsorbent fabrics (no coating required), such as ponchos, baby pants, faux leather jackets and various rain boots. Polyvinyl chloride is used in many sports and entertainment products, such as toys, records and sports goods, and PVC toys and sporting goods have grown significantly and have advantages due to their low production costs and ease of molding.

PVC coated products

- Artificial leather with a substrate is made by applying PVC paste to cloth or paper and then plasticizing it at temperatures above 100 °C. It can also be made by calendering PVC and additives into a film and then pressing it with a substrate. Artificial leather without substrate is directly rolled into a soft sheet of a certain thickness by a calender, and then pressed with a pattern. Artificial leather can be used to make suitcases, bags, book covers, sofas and car cushions, etc., as well as floor leather, which is used as a flooring material for buildings.

PVC foam products

- When soft PVC is mixed, an appropriate amount of foaming agent is added to make sheets, which are foamed into foam plastics, which can be used as foam slippers, sandals, insoles, and shockproof cushioning packaging materials. It can also be used as a basis for extruder into low-foaming hard PVC sheets and profiles, which can replace wood and is a new type of building material.

PVC transparent sheet

- PVC is mixed with impact modifier and organotin stabilizer to become a transparent sheet after mixing, plasticizing and calendering. It can be made into thin-walled transparent containers or used for vacuum blister packaging by thermoforming, which is an excellent packaging material and decorative material.